COALTECH

CoalTech Ltd was founded to pursue the very large opportunity which exists in turning the global stockpiles of ca. 35bn tons of coal fines into usable products. Since 2013, the firm has invested ca. $6m in research and development, principally in South Africa, one of the world’s largest coal producers and users. The firm developed an initial lab-scale demonstration project and tested various potential binders, before moving on to a small demonstration facility and, eventually, to an industrial scale demonstration plant. This demonstration plant has been commissioned in late 2018 and operates near Witbank in South Africa.

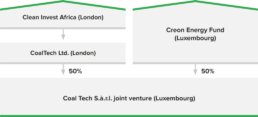

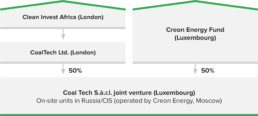

All projects are being realize by CoalTech S.à.r.l., a Luxembourg-based Joint-Venture of Clean Energy Africa, an LSE-listed investment company and parent to CoalTech, and the Creon Energy Fund. The latter’s parent is the consulting, management and investment company Creon Energy, which also manages the CoalTech activities. The Luxembourg entity owns and operates the units on the ground via local subsidiaries, which are committed to regional sourcing, engineering and construction.

The ownerships structure of the Joint-Venture.

The ownerships structure

of the Joint-Venture.

For almost 20 years, Creon Group has been instrumental in the realization of numerous large-scale projects in the regions energy sector. Registered as a consulting company in 2002, Creon companies created a vast network of business contacts in the energy sector and chemical industries all over Europe. Today, the CoalTech operator Creon Energy is a center of expertise for the energy, oil and gas downstream industries.

In 2016, the Creon Energy Fund has been licensed as a SICAV-SIF Private Equity Fund in Luxembourg. The regulated Fund eyes investments in oil and gas downstream industries, liquefied natural gas (LNG), green technologies and logistics.

Clean Invest Africa accompanied the CoalTech innovation from the early development stage through patenting to the upscaling stage, which the successfully piloted technology reached in 2018.

COAL WASTE TO ENERGY

CoalTech’s innovate technology and proven process allows mining companies to turn this inevitable waste produce into pellets (pea or nut size), which can be handled in the existing coal supply chain infrastructure. Having solved this critical materials handling and storage problem, coal fines which previously were only a financial liability can now be used to increase mine output, revenues, or to reduce costs where customers were previously unable to make effective use of the fines accumulating at their facilities. Critically, the characteristics of the pellets are the same as those of the coal fines — they are, for all practical purposes, identical to mined coal.

OUR VISION

We acknowledge that coal remains a key energy source for the upcoming century. Yet we believe passionately that the environmental impact of coal mining and processing can be reduced tremendously. We are contributing to a cleaner and greener coal industry by recycling harmful coal fines. This is essential, especially in emerging markets, where easily accessible and cheap energy is an important contributor to economic growth, and the volume of coal usages continues to increase.

OUR MISSION

We understand that mining companies are reluctant to invest in green technologies without receiving commercial benefits in return. Therefore, we designed a patented solution to process coal waste to a valuable products which are equivalent to mined coal and can be used as such across the coal value chain. Our mission is to deploy this unique solution as widely as possible, to reduce the amount of environmentally harmful coal fines, decrease pollution, create jobs and, in turn, create value for our customers.

OUR VISION

We acknowledge that coal remains a key energy source for the upcoming century. Yet we believe passionately that the environmental impact of coal mining and processing can be reduced tremendously. We are contributing to a cleaner and greener coal industry by recycling harmful coal fines. This is essential, especially in emerging markets, where easily accessible and cheap energy is an important contributor to economic growth, and the volume of coal usages continues to increase.

OUR MISSION

We understand that mining companies are reluctant to invest in green technologies without receiving commercial benefits in return. Therefore, we designed a patented solution to process coal waste to a valuable products which are equivalent to mined coal and can be used as such across the coal value chain. Our mission is to deploy this unique solution as widely as possible, to reduce the amount of environmentally harmful coal fines, decrease pollution, create jobs and, in turn, create value for our customers.

OUR ADVANTAGE

We do not sell our technology. Running a CoalTech plant will not require any investment by a coal mining company or other partners. The stakeholders along the coal value-chain are suppliers of raw material, which is typically a waste stream for them, and a customer for the final product. We agglomerate this waste product into to saleable products and return it to the mining companies’ sales channels, or another partner’s existing coal handling infrastructure. Our product is identical to coal and can therefore be blended with mined coal, or shipped and used on its own.

OUR VALUES

We are committed to the principles of Bettercoal, an industry initiative set up to improve environmental and social standards along the coal supply chain. We support mining companies by eliminating toxic coal fines. This is increasingly an important consideration during on-site audits, which Bettercoal specialists conduct regularly, aiming to ensure improvements across the industry. Cleaning up slurry ponds and fines dumps is an easy and financially attractive step towards a better environmental profile, as remediation provisions can be reduced, and the waste product can be sold as normal coal.

OUR ADVANTAGE

We do not sell our technology. Running a CoalTech plant will not require any investment by a coal mining company or other partners. The stakeholders along the coal value-chain are suppliers of raw material, which is typically a waste stream for them, and a customer for the final product. We agglomerate this waste product into to saleable products and return it to the mining companies’ sales channels, or another partner’s existing coal handling infrastructure. Our product is identical to coal and can therefore be blended with mined coal, or shipped and used on its own.

OUR VALUES

We are committed to the principles of Bettercoal, an industry initiative set up to improve environmental and social standards along the coal supply chain. We support mining companies by eliminating toxic coal fines. This is increasingly an important consideration during on-site audits, which Bettercoal specialists conduct regularly, aiming to ensure improvements across the industry. Cleaning up slurry ponds and fines dumps is an easy and financially attractive step towards a better environmental profile, as remediation provisions can be reduced, and the waste product can be sold as normal coal.

A PROVEN, SCALABLE TECHNOLOGY

MEET OUR EXPERIENCED TEAM

FILIPPO FANTECHI

CoalTech Ltd.

Founder & Owner

As the president and majority owner of shareholder Contax Partners, Mr. Fantechi backs CoalTech. He takes responsibility for strategic decisions related to fundraising and expansion, while the group benefits from his 30-plus years of professional experience in business development, project management, sales, operations and market strategy development in the Middle East, Europe and Africa.

VLADIMIR VOLOSHIN

CoalTech S.à.r.l.

Chief Operating Officer

As a mechanical engineer with an economic background and certified PMP project manager, Mr. Voloshin has gained tremendous experience in the implementation of large industrial projects, including greenfield construction in the mining, chemical and automotive industries. Prior to running CoalTech operations, he helped to build the Mercedes-Benz plant on behalf of Thost Projektmanagement (Germany).

AURELIO DI FRESCO

CoalTech S.à.r.l.

Chief Executive Officer

Mr. Di Fresco is responsible for the coordination of CoalTech’s daily business, projects, logistics and strategic planning. He is passionate about achieving high levels of efficiency in process development, engineering, project execution, production, R&D and QHSE certifications. He has over 30 years of experience in the management of projects and operations within the Middle East, Europe and Africa.

CHRISTIAN ENDTER

CoalTech Ltd.

Business Development Officer

Born in Germany, Christian has spent most of his career in the financial services industry, living in London, Toronto, New York, and Johannesburg, where he joined CoalTech. Now a business professional with almost 20 years of experience across IT, banking, asset management and insurance, he oversees the company’s business development efforts and works globally on partnerships, project development and financing.

DANIE VAN TONDER

CoalTech Ltd.

Head of Engineering

Responsible for man- aging all process and engineering related disciplines as well as interface and support duties for the R&D department, facilitating the development and upgrading of the CoalTech technology. He closely monitors the quality of existing and new projects. Mr. Van Tonder brings over 20 years’ experience in process design and engineering disciplines for the mining, minerals and energy resources sector.

YURY RATNIKOV

Creon Energy

Senior Project Manager

Prior to Creon Energy, Ratnikov gained vast experience in managing projects for VW, Renault, OBI, Kesko, Castorama, Metro CC, KSB, Doka and IKEA. Be- fore he started his project management career in 1999, he graduated with a Ph.D. in technical science, later receiving certifications as a professional scrum master and senior quality auditor by a TÜV quality certification group.

SANDJAR TURGUNOV

Creon Group

General Manager

Sandjar Turgunov has been working with Creon since the company was founded and developed extensive experience in marketing. His responsibilities include the management of oil and gas activities, supervision of investment projects and the implementation of the group’s development strategy.